As I mentioned in my last newsletter, the 179d federal tax deduction for energy efficient buildings expired on January 1 of this year. Any project completed before this date can still be certified for a deduction on your 2016 taxes. Congress continues to discuss extending the tax deduction, but little formal action has been taken. All of the current extension bills are awaiting action in various committees. Stay tuned to our website for any updates on the extension efforts.

As you may know, we regularly post links to our articles on our Facebook and LinkedIn pages. This month we added a Twitter account which you can follow to get updates on new posts. Here’s what we were talking about this month:

- Variable Speed Fans on HVAC Units – One of the most common recommendations we make to clients is to consider installed variable speed fans on their HVAC equipment.

- Why not Take the Train? – A friend asked me how much coal it takes to get to Maine. I’m not that kind of engineer but I took on the challenge.

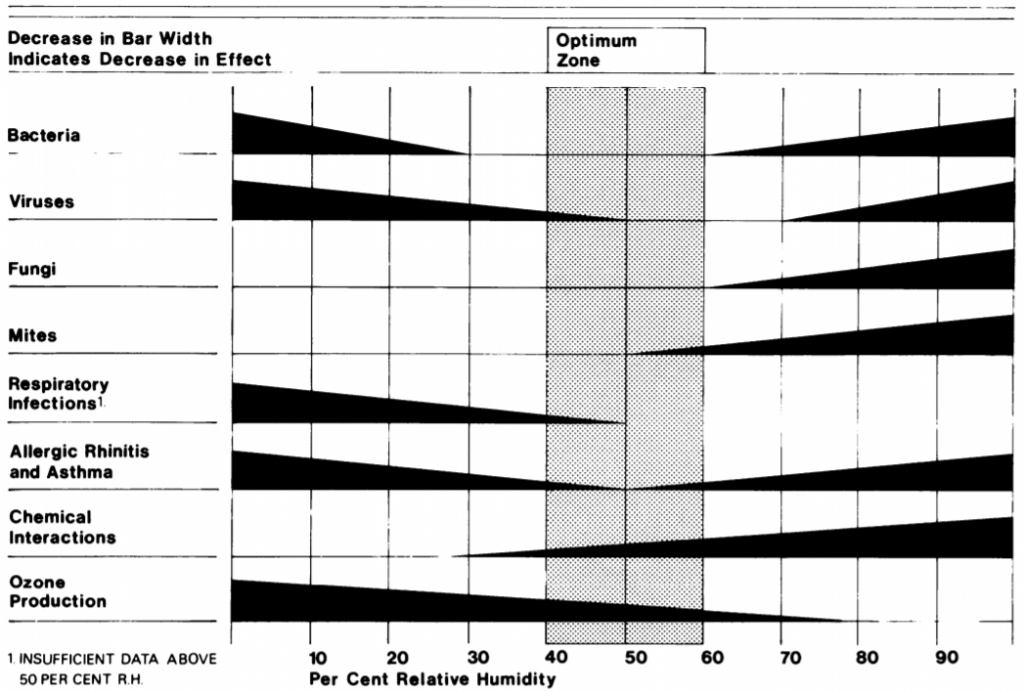

- Humidity and Healthy Air – You may already know the effects of humidity on comfort, but did you know it can also influence your health?

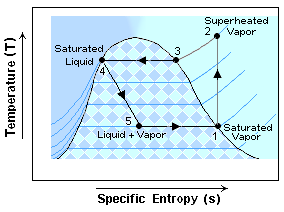

- Cooling off with Sunscreen – Ever notice how a spray can is cold after use? You just experienced a principle of refrigeration.

Be sure to check our website regularly for updates or follow us on Facebook, LinkedIn or Twitter. We wish you the best this month and if you ever have need of any of our services, please don’t hesitate to contact us. Have a great day!

If you would like to receive these newsletters in your inbox, just sign up below. Be sure to check what services you are interested in before clicking Subscribe.